Water treatment

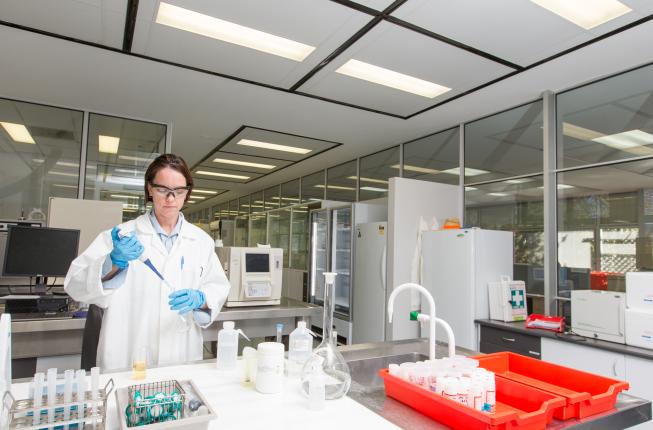

South East Queensland has some of the highest quality drinking water in the world, thanks to our effective water treatment processes. Drinking water is cleaned and treated at our water treatment plants to the stringent standards set by the Australian Drinking Water Quality Guidelines.

To ensure a consistent, high quality drinking water supply we currently operate 32 water treatment plants across the region. The Mt Crosby East Bank and West Bank water treatment plants are the primary source of drinking water for the greater Brisbane and Ipswich areas, having the greatest production capacity. Molendinar and Mudgeeraba on the Gold Coast, North Pine to the north of Brisbane, and Landers Shute on the Sunshine Coast are the other main treatment plants for the region.

Our interconnected supply network allows us to move water from these plants across the region to where it is needed most. This ensures a consistency of supply if one part of the network is affected by weather, maintenance or other issues.

Seqwater also manages climate-resilient sources of water: the Gold Coast Desalination Plant and the Western Corridor Recycled Water Scheme. These assets ensure that South East Queensland will always have a safe, secure source of water – rain, hail or shine.

New PFAS guidelines provided by the National Health and Medical Research Council (NHMRC).

Seqwater welcomes the release of the updated draft Australian Drinking Water Guidelines (ADWG) on PFAs by the NHMRC.

We support the rolling review of the ADWG in line with the latest scientific data to maintain clean, safe and sustainable drinking water across South East Queensland for generations to come.

Drinking water

Effective treatment ensures the drinking water the South East Queensland community receives meets stringent standards. Water treatment currently takes place at locations across the region including from Molendinar and Mudgeeraba on the Gold Coast, Mt Crosby to the west and North Pine to the north of Brisbane, and Landers Shute on the Sunshine Coast.

The processes and technologies used to remove contaminants from raw water and to improve and protect water quality are similar to those used all around the world. The most widely applied water treatment process – known as conventional treatment – is a combination of coagulation, flocculation, sedimentation and filtration, and is used by the majority of Seqwater’s treatment facilities.

Innovative water treatment technologies are becoming more and more important in response to the challenges associated with some of our raw water sources. Advanced water treatment – comprising conventional treatment plus additional process streams such as ozonation and biological activated carbon filtration – enhance the removal of toxins, organic matter, pesticides and disinfection by-products. These advanced treatment processes are used at the Landers Shute, Ewen Maddock, and Noosa facilities on the Sunshine Coast, and Banksia Beach Water Treatment Plant on Bribie Island.

Desalination

The Gold Coast Desalination Plant turns sea water into drinking water. As a climate-resilient source of water, the plant regularly supplies drinking water to the Water Grid, and ramps up in times of flood or drought, or when conventional water treatment plants are offline.

The Gold Coast Desalination Plant, located at Tugun, uses reverse osmosis to produce drinking water for the Gold Coast, Logan and Brisbane. The plant’s intake and outlet structures are located out to sea and have become artificial reefs, which are home to a variety of small plants and sea animals.

The process

The desalination process separates dissolved salts and other minerals from seawater to produce drinking water.

It uses an advanced technology called reverse osmosis to remove the salt. The water produced is called permeate and is similar to distilled water. Permeate is then re-mineralised so it can be blended with other treated water or directly distributed to homes, businesses and industries in the region.

Unlike the majority of drinking water produced in South East Queensland, desalination does not rely on rainfall and is a critical, climate resilient water source during drought and flood.

Read About the Gold Coast Desalination Plant fact sheet for more information.

Purified recycled water

The Western Corridor Recycled Water Scheme is a climate-resilient source of water that will help provide water security in times of need. The scheme is maintained regularly but is not currently supplying purified recycled water for drinking. A part of the scheme is operational and supplying purified recycled water for power generation.

The Western Corridor Recycled Water Scheme can be restarted to supply purified recycled water for drinking when required as one of our drought response measures to assist long-term water security for the region.

In South East Queensland, treated wastewater intended for recycling is sent to advanced water treatment plants at Bundamba, Gibson Island and Luggage Point. At the plants, treated wastewater is filtered and then passed through a number of processes including membrane filtration, reverse osmosis and advanced oxidation to produce purified recycled water.

The purified recycled water is then pumped to Wivenhoe Dam, where it blends with rainwater runoff stored in the dam. Water is then treated again at water treatment plants downstream at Mt Crosby, before being delivered to homes and businesses. The advanced water treatment plants can produce about 180 million litres a day or about 20% of current demand.

Water quality

South East Queensland has some of the highest quality drinking water in the world, thanks to our effective water treatment processes.

Reporting

Water undergoes regular and thorough testing at many points of the treatment and distribution system to make sure drinking water quality meets the stringent standards outlined in the Australian Drinking Water Guidelines 2011.

Seqwater publicly reports on the quality of the bulk drinking water supply every month. The report provides information on the typical quality of the bulk water supply to councils in South East Queensland against 40+ key health and aesthetic water quality parameters.

Continuous improvement

Seqwater is further enhancing water treatment processes at its Mount Crosby and North Pine water treatment plants to deliver water quality benefits to communities in the Ipswich, Brisbane, Logan and Moreton Bay regions and some parts of the Scenic Rim.

The enhanced treatment processes will further stabilise water quality including during the summer months when water quality needs to be more closely managed.